Every pneumatic tyre fitted to a motor vehicle first used from 1st April 1987 must comply with the C & U requirements on tyre loads and speed ratings. This means that the vehicle’s tyres must be designed to suit its maximum legal axle weights and its maximum legal speed.

Exemptions from this rule include vehicles used for multi-stop local collection and deliveries (within a 25-mile radius of the vehicle base) which need tyres adequate for speeds of up to 40 mph only.

Recut tyres may only be fitted to goods vehicles of 2540kg unladen weight or more and having a wheel diameter of 405 mm or over, and any electrically propelled goods vehicle.

Tyres fitted to a vehicle or trailer must:

Tyres manufactured from 1 July 2012 are labelled with official ratings for fuel efficiency, wet grip and noise.

Fuel efficiency and wet grip is rated from A – G.

Noise is rated in decibels accompanied by one, two or three waves on the label, one wave being the best performance and three the worst.

Buying part worn tyres – what operators need to know

A tyre that has previously been fitted and worn on another vehicle is known as a “part worn tyre”.

This also applies if you purchase a second-hand vehicle and do not replace the tyres.

Buying and fitting part-worn tyres is not illegal.

However, there could be serious road safety risks if there is an underlying issue with a part worn tyre fitted.

Christopher Lowe, a DVSA Market Surveillance Unit investigations manager shares his findings from recent investigative work and explains how you can make sure you are buying and fitting compliant part-worn tyres.

Read – https://movingon.blog.gov.uk/2022/12/07/buying-part-worn-tyres-what-operators-need-to-know/

Why Are Tyres So Important?

Tyres are the only contact point between your vehicle and the road. Providing essential grip when accelerating and braking. Tyres must strike a balance between comfort, durability, fuel efficiency, and grip, and there are many other factors that a tyre designer must consider.

Tyres are far more than just a rubber compound. Tyres support the entire weight of the vehicle, absorb shocks sent from the road surface, and help ensure the vehicle maintains a stable course on the road.

Tyre construction

A Tyre is seen as being made from a single substance. It is in fact a complex assembly of various components. Tyres are made from 200 different raw materials.

Their rubber is made from four types of materials

Tyres also include Steel and Textile products.

Tyre Usage

In their infancy, tyres were used solely for bicycles and tricycles. Now, they cater to a plethora of vehicles and transport options. Bikes, cars, planes, and trains — the list is endless.

As of 2010, the number of passenger cars in the world reached the one billion mark for the very first time, acting as an example of the sheer number of tyres required. From motorsport to everyday use, tyres are crucial in ensuring our safety when driving.

Source – Michelin

The Road Vehicles (Construction & Use) Regulations 1986.

The relevant section of the Road Vehicles (Construction & Use) Regulation 1986 relating to tyres can be found at the following sections:

Regulation 25 – Tyre loads and speed ratings

Regulation 26 – Mixing of tyres

Regulation 27 – Condition and maintenance of tyres

Source – C&U Regulations

Tyre Defects and Damage – HGVs, Buses and Trailers

The following comes from the DVSAs Tyre Defects and Damage which relations to Heavy Goods Vehicles, Buses and Coaches and Trailers.

Following each image, there is information concerning if the vehicle concerned is stopped at a roadside check, attending at an MOT test station and also notes the reason for the action that may or may not be taken against the operator.

Summary of legal requirements

Minimum tread depth 1mm (vehicle over 3,500kg gross vehicle weight) over a continuous band covering at least any three-quarters of the breadth of the tread around the entire circumference.

The base of any groove of the original tread pattern must be visible on the remaining one-quarter of the tread.

‘Breadth of tread’

‘Breadth of tread’ means the part of the tyre in contact with the road, under normal use and measured across the tyre.

‘Original tread pattern’

The ‘original tread pattern’ means:

These things are excluded from the term ‘original tread pattern’:

IRREGULAR TYRE WEAR

Irregular tread wear, with more than 1mm tread depth

over more than three-quarters of the tread area.

The following situations are applicable.

Roadside inspection

Inspection Notice

MOT (annual test)

Pass (advise at discretion of assessor).

Reason

Depth of tread is greater than 1mm throughout the circumference of a band covering at least three-quarters of the tread width & the base of any groove of the original tread pattern is visible on the remaining one-quarter of the tread

Irregular tread wear, less than 1mm tread depth

over less than three-quarters of the tread area.

The following situations are applicable.

Roadside inspection

Immediate Prohibition

MOT (annual test)

Fail – Dangerous* – Tyre tread worn below the legal minimum on any tyre fitted to a steered axle and/or 50% or more of the total number of tyres fitted to non-steered axles.

Reason

Remaining legal tread pattern covers less than three-quarters of the tread width.

The base of any groove of the original tread pattern is not visible on the remaining one-quarter of the tread.

Flat spot, less than 1mm tread across three-quarters of the tyre tread,

and exposed cords in the tread area.

The following situations are applicable.

Roadside inspection

Immediate Prohibition

MOT (annual test)

Fail for tread Dangerous* – Tyre tread worn below the legal minimum on any tyre fitted to a steered axle and/or 50% or more of the total number of tyres fitted to non-steered axles.

Fail for cord exposed. (Dangerous* – PG9 may be issued if failure of the tyre is likely)

Reason

Cords exposed.

Depth of tread is not greater than 1mm throughout the circumference of a band covering at least three-quarters of the tread width.

The base groove of the original tread pattern is not visible on the remaining one-quarter of the tread.

SIDEWALL ABRASION

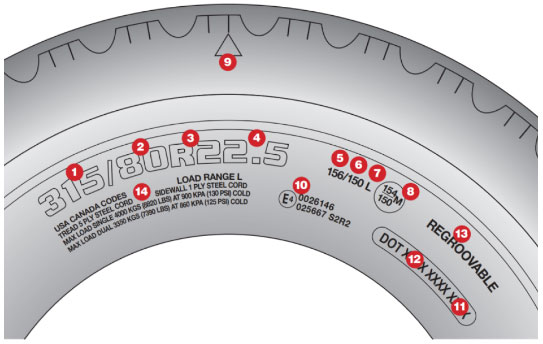

Tyre markings

A tyre will need to display markings indicating it is suitable for the application, nominal size, load index/ply rating, speed rating and tyre age code.

Sidewall heavily abraded with regulatory date markings illegible,

no cords visible, overheating or other damage evident

The following situations are applicable.

Roadside inspection

Front steered axle or any single wheels fitted to a minibus – Delayed prohibition.

Any other position – inspection notice.

MOT (annual test)

Front steered axle or any single wheels fitted to a minibus – Fail major defect.

Fitted to any other position – Pass minor defect.

Reason

Where regulatory date makings are not visible on at least one sidewall, a check will be made on the opposing sidewall. A check will be made visually for evidence of deterioration.

Where there is clear evidence of tyre deterioration, the roadside inspection would be increased to an immediate prohibition action for front-steered axles and any single wheels fitted to a minibus.

Body cords exposed on the sidewall

The following situations are applicable.

Roadside inspection

Immediate prohibition.

MOT (annual test):

Fail (Dangerous* – PG9 may be issued if failure of the tyre is likely)

Reason

Body cords visible/damaged.

DAMAGE

Summary of legal requirements

The cords must not be visible. This applies to any type or size of wear or damage condition, examined with or without the use of a blunt probe.

Where damage or cuts are larger than 25mm or 10% of the section width (whichever is the greater), the cords must not be detectable on examination with a blunt probe.

Sections of tread must not be partially separated from the tyre.

Any sidewall bulges must not be spongy or easy to depress.

Use this criteria when you assess a cut in a tyre:

Cuts which are deep enough to reach the cords or ply but are less than 25mm or 10% of the section width (whichever is the greater), and have not damaged or exposed the cords or ply do not breach the legal requirements for tyres.

Tread Separation

The following situations are applicable.

Roadside inspection

Immediate prohibition.

MOT (annual test)

Fail (Dangerous- PG9 issued).

Reason

Section of tread partially separated: risk of rubber detachment.

A cut less than 25mm to the tread area and less than 10% of the

section width, with no cords damaged or exposed

The following situations are applicable.

Roadside inspection

With the use of blunt probe. Unable to detect cords; Pass.

MOT (annual test)

With a blunt probe unable to detect cords – pass.

Reason

Cuts, which are not deep enough to reach the cords or ply, but are less than 25mm or 10% of the section width, whichever is the greater, do not breach the legal requirements for tyres.

Cut to tread exposing cords

The following situations are applicable.

Roadside inspection

Cords visible; Immediate prohibition.

MOT (annual test)

Fail (Dangerous* – PG9 may be issued if failure of the tyre is likely).

Reason

Cords visible in tread area.

Tyre tread cut to create a rubber flap exposing cords

The following situations are applicable.

Roadside inspection

Cords exposed and visible in tread area; Immediate Prohibition.

MOT (annual test)

Fail (Dangerous* PG9 may be issued if failure of the tyre is likely).

Reason

Cords visible in tread area.

Tyre regrooved too deep

The following situations are applicable.

Roadside inspection

Cords exposed; Immediate Prohibition

MOT (annual test)

Fail (Dangerous* PG9 may be issued if failure of the tyre is likely)

Reason

Cords visible in tread area.

Bulge in sidewall is easy to depress (spongy)

The following situations are applicable.

Roadside inspection

Tyre bulging caused separation or partial failure of its structure; Immediate Prohibition.

MOT (annual test)

Fail (Dangerous – PG9 issued)

Reason

Casing separation.

Minor crazing (fine cracks) on the sidewall,

but with no cords exposed

The following situations are applicable.

Roadside inspection

Pass.

MOT (annual test)

Pass.

Minor cracking in grooves, no cords exposed

The following situations are applicable.

Roadside inspection

Pass.

MOT (annual test)

Pass.

Tyre age code 3307 fitted to HGV front-steered axle

The following situations are applicable.

Roadside inspection

Tyre age more than 10 years old: Immediate Prohibition.

MOT (annual test)

Tyre age more than 10 years old: Fail Dangerous PG9 Issued.

Tyre age code manufactured week 33 of year 2007. Tyre age code must be present.

Tyres more than 10 years old shall not be fitted to front steered axle/s and any single wheel configuration on a minibus. If it is a retreaded tyre, check the retreading tyre age code.

Incorrect tyre regroove pattern

The following situations are applicable.

Roadside inspection

Tyre regroove pattern incorrect; Inspection Notice.

MOT (annual test)

A wholly or partly recut tread pattern is not to the manufacturers recut tread pattern; Fail Major.

Source – DVSA